| Step Mill with Dual Edge Insert |

|---|

|

|

B.E.S. Carbide Dual Edge Step Mills are engineered for smooth action and high machining efficiency on applications where lack of rigidity causes deflection or vibration.

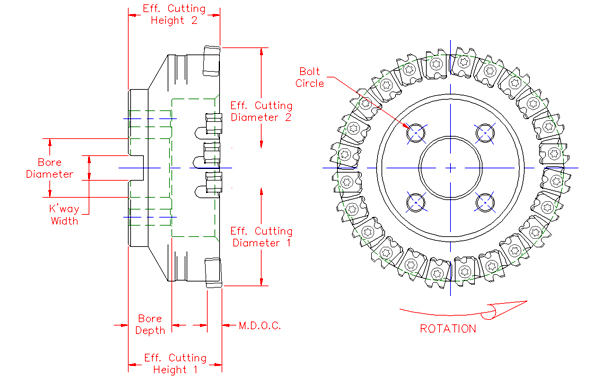

Radial and axial stepping reduces the effective number of inserts and the depth of engagement of each insert in the workpiece. Step mills take short, thick chips rather than long chips. This design reduces cutting forces while maintaining the advance per insert, depth of cut, and width of cut.

These mills have a lesser number of effective inserts, that is, it takes more than one insert to generate a full chip. But, since the chip is not as wide, the chip load can be increased to compensate. This cutter can generally be run without reducing the feed rate.